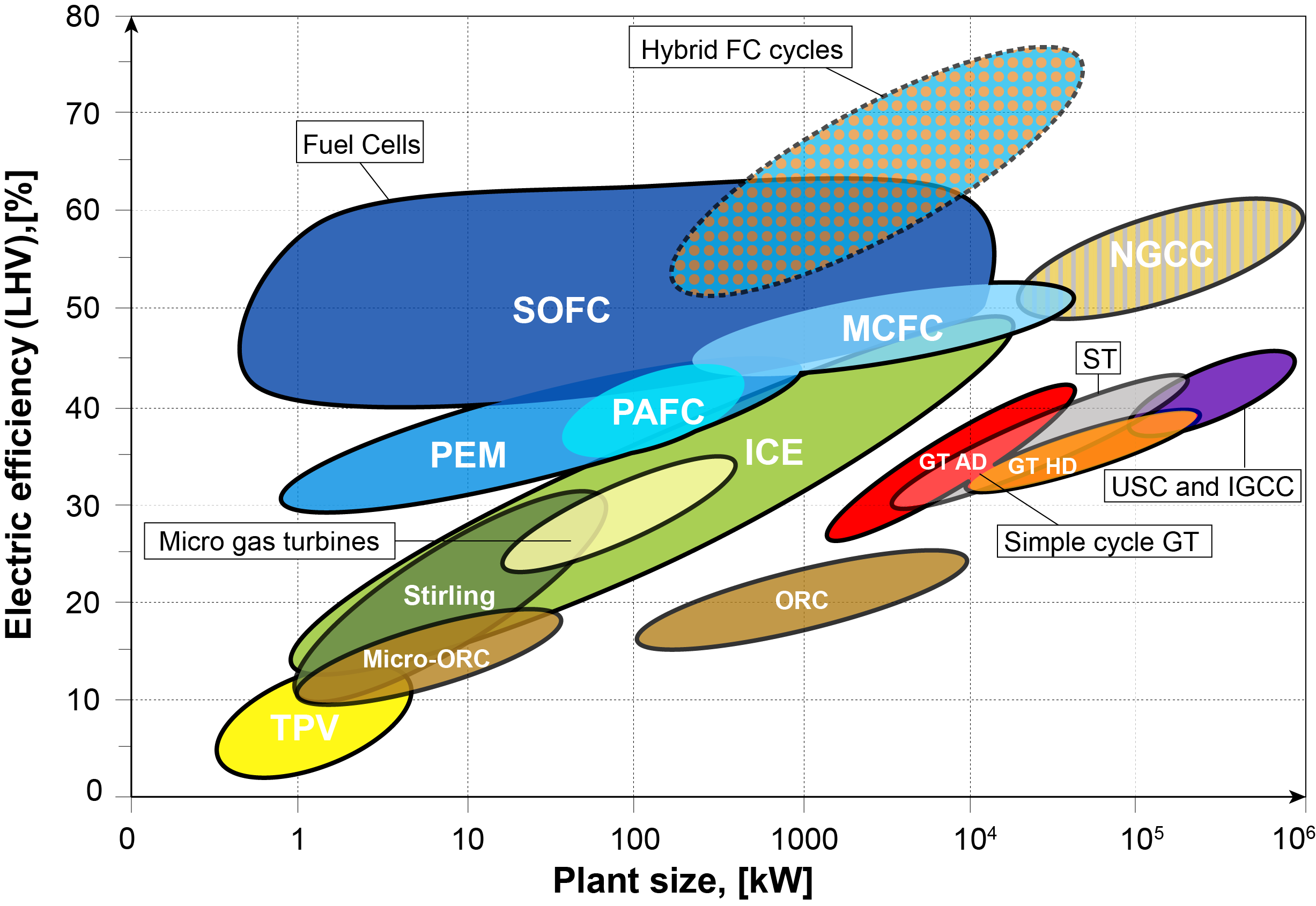

Fuel cells and electrochemical energy systems in general are a focus of our group since many years, starting from original work in the late 90s on hybrid Solid Oxide Fuel Cell-Gas Turbine (SOFC-GT) cycles for very high-efficiency energy conversion.

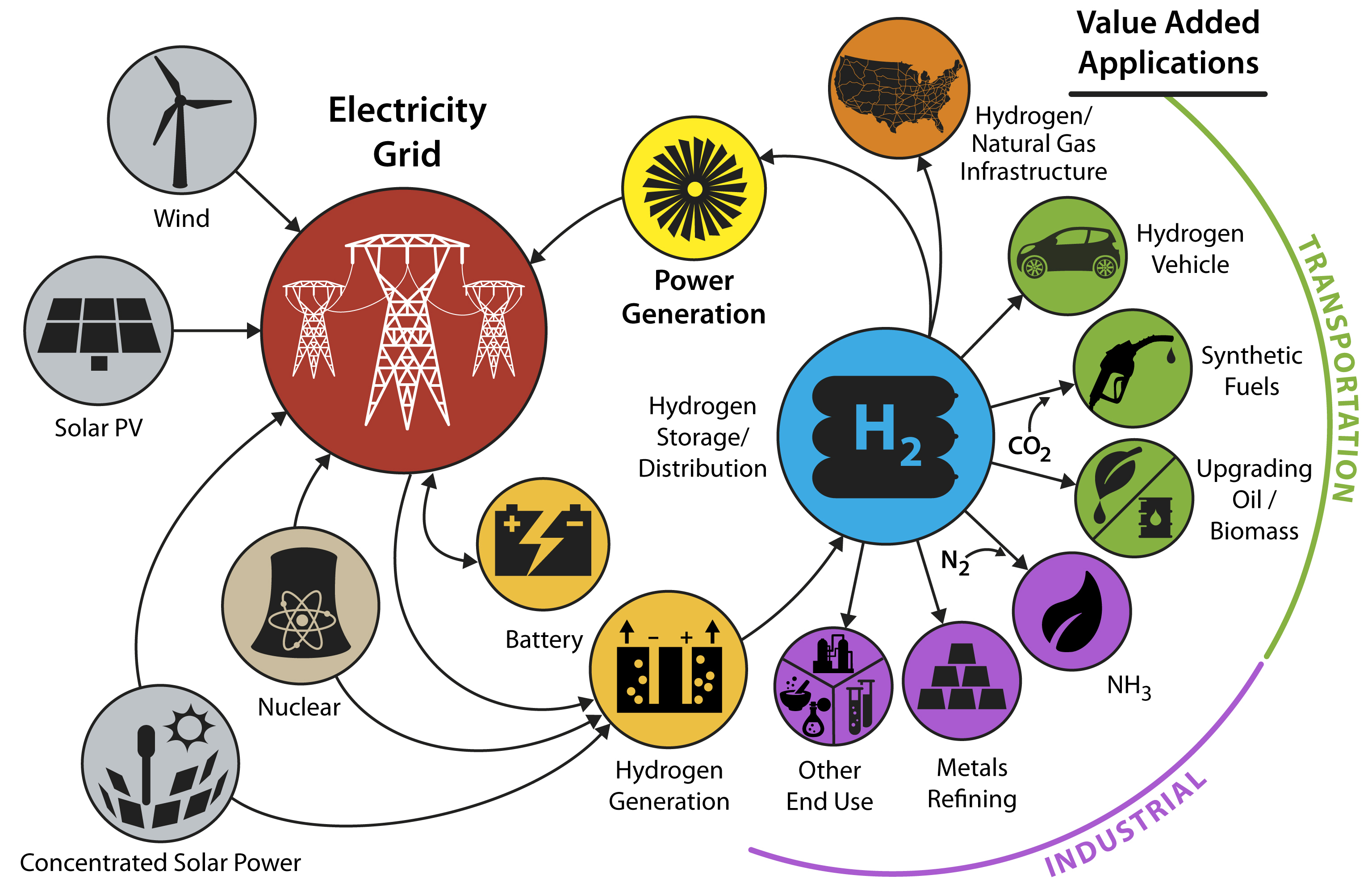

Research activities focus on high- and low-temperature electrochemical systems (i.e., SOFC, MCFC, PEMFC) for distributed and centralised high-efficiency power generation, as well as on hydrogen production through electrolysis (alkaline, PEM, SOE) and other low-CO2-emission processes. Moreover, reversible electrochemical systems are extensively studied as storage technologies associated with the production of synthetic fuels and power-to-gas. Applications of fuel cells for Carbon Capture and Storage are also addressed in depth.

The group is also active within the Fuel Cell and Hydrogen Initiative of the Department of Energy of Politecnico di Milano - www.fch.polimi.it

Energy conversion with fuel cells

Simulation of hydrogen energy systems for stationary or mobile applications

Finite volume (1-3D) and CFD simulation of PEMFC, MCFC, and SOFC

Testing of PEMFCs, SOFCs, and other small-scale power generation units in the Laboratory of Micro-Cogeneration (up to 100 kWe)

Analysis of mass and energy balances through measurements and detailed system modelling

Simulation of large-scale power generation with Carbon Capture, adopting SOFC and MCFC + CCS power plant

Simulation of reversible solid oxide systems (rSOC) for grid management and energy storage in presence of fluctuating renewables

Simulation of reversible molten carbonate systems (rMCC) with coupled renewables and natural gas grid connection

Hydrogen Technologies

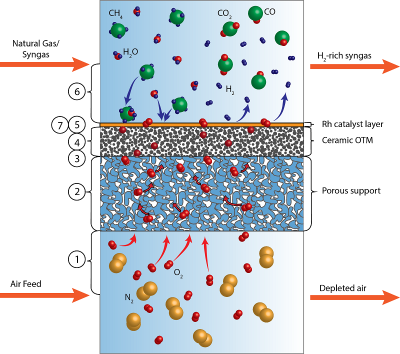

Hydrogen production from fossil fuels and co-production of hydrogen and electricity with CO2 capture

Hydrogen production through membrane fuel processors

Hydrogen production through low- and high-temperature electrolysis, focusing on Power-to-Gas (P2G) applications for energy storage and sector coupling (NG grid injection)

High-efficiency hydrogen liquefaction

Power-to-Hydrogen (P2H) and Power-to-Gas (P2G)

Long-term potential for surplus electricity recovery from RES at the regional and country scale

P2G and PV/wind coupling optimisation, dynamic operation, competition with other fast-ramping technologies

Hydrogen blending in natural gas pipelines and quality tracking

Integration of the electric grid with BEV and H2-FCEV mobility (multi-nodal modeling at country scale, dispatch modeling, storage system analysis; driving cycle simulations for light and heavy duty vehicles)

Assessment and comparison of hydrogen delivery modes

For further information on hydrogen and electrochemical systems, please contact Prof. Stefano Campanari (stefano.campanari@polimi.it).

Recent publications

Sorry, no publications matched your criteria.